1 / 1

PSA oxygen generator for medical hospital application

| Model No. : | POMH |

|---|---|

| Brand Name : | Gamma Gas |

| Usage : | Oxygen |

Jinan, Shandong, China

- Agente

- Distributoregrossista

- Produttore

- Rivenditore

- Servizio

- Compagnia commerciale

- Servizio OEM

- Certificazione della piattaforma

Descrizione del prodotto

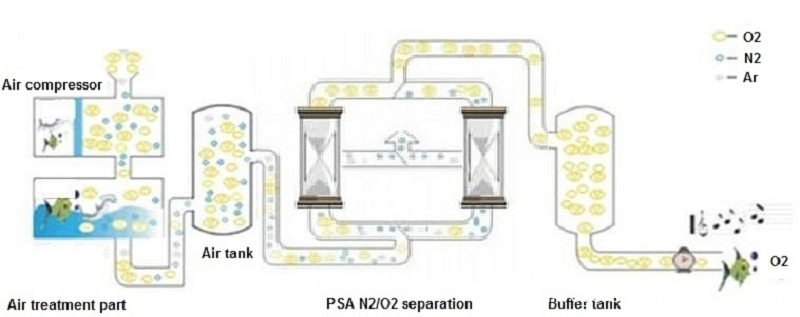

PSA oxygen generator for medical hospital application is one kind of machine producing 90-99% purity oxygen for medical and hospital applications. It adapts the principle of PSA, which is pressure swing adsorption. This technology separates and collects oxygen from air. Raw material is compressedairsupplied by air compressor. First the compressed air is to be cleaned and dryed by one air treatment part which includes air filters, dryer and oil remover, then air is passed through adsorption towers containing adsorbent(zeolite molecular sieve) bed, in this tower, nitrogen is adsorbed, the gas coming out of the vessel will be enriched in oxygen. This oxygen is collected as product gas, after flow rate adjustment and pressure buffering, it is sent to using point.

One oxygen generator has several parts like below:

Oxygen concentrator specification

Oxygen flow rate: 5-300 Nm3/Hr

Oxygen purity: 90-99%

Oxygen outlet pressure: 5-200 bars

Parts introduction

A complete oxygen generator consists of: Air compressor, PSA oxygen generator, buffer tank,etc

Air compressor

Function: Air compressor provides compressed air source for the PSA oxygen generation part, the flow and pressure are to be decided by the desired oxygen flow rate, purity, outlet pressure. As it is the air source of whole system, the performance of air compressor has remarkable influence to the whole oxygen generator system

Air treatment part

Function: get rid of water, oil, impurities in compressed air coming from the air compressor, providing clean, dry, oil-free compressed air for the PSA oxygen generation part. It includes 3 filters, 1 refrigerated dryer and 1 activated carbon oil remover. After treatment, dew point of compressed air can reach -20 degree (normal pressure) , dust content is not larger than 0.01mg/m3, solid particles diameter is not larger than 0.01μ, oil mist content is not more than 0.003mg/m3.

Air tank:

It quickly increases the pressure of adsorber;

PSA oxygen separator:

It is the key part of whole system. In this part, the oxygen is separated from compressed air, sent to buffer tank as produced gas. Nitrogen, carbon dioxide, argon,etc are discharge from muffler as exhausted gases. The efficiency of this machine is mainly decided by adsorption tower structure, air distribution structure, molecular sieve performance, process flow, etc.

Oxygen buffer tank:

It balances pressure fluctuation, ensure stable oxygen supply;

Gamma Gas oxygen generator features

High reliability:

Proven PSA technologies such as big flange structure, snowstorm filling, gas distribution system, gas speed control technology, unequal pressure balance system,etc make Gamma Gas oxygen generator more reliable than many other suppliers. Easy installation:

Skid structure, fully assembled and test qualified before delivery. When machine reaches site, with simple connection of power supply and gas pipeline, the machine is ready for operation. No need to disassemble and/or re-assembly at site.

Convenient operation:

Fully tested before delivery. With a simple touch on Siemens touch screen, machine starts to run, no need for valves adjustment,etc.

Minimized maintenance:

After 8000 hours operation, simply replace the three filter elements and activated carbon for air treatment part, no other regular maintenance needed.

Low operation cost:

With Gamma Gas special technologies, producing same flow rate, same purity oxygen, smaller compressed air is needed, saving customer air compressor electricity consumption cost every day.

Quality guaranty

Quality guaranty period:

15 months after equipment factory delivery or 12 months after equipment site operation inspection acceptance, whichever occurs first; Within this period of time, any trouble occurred because of the oxygen generator, Gamma provide free guidance, free parts. If necessary, Gamma engineers go to site at Gamma`s own cost.

Site commissioning service

If necessary, the seller is to provide free site operation and maintenance training. If site service is provided, the customer is to provide charges for visa application, round trip air tickets, board and lodge charges, transportation charges, etc for not more than two Gamma service engineers.

After training, operation personnel are to be able to operate the equipment efficiently;

After training, the maintenance personnel are to be able to master daily maintenance and repair knowledge;

At the buyer`s requirement, the seller is to provide more free training service;

Customer care

Every year, at least one time thorough survey to check the operation condition and provide related advice to optimize the equipment;

Service response time

Upon reception of the notice of equipment failure, within 24 hours, provide the best solution and guidance.

Jinan, Shandong, China

- Agente

- Distributoregrossista

- Produttore

- Rivenditore

- Servizio

- Compagnia commerciale

- Servizio OEM

- Certificazione della piattaforma

Invia la tua richiesta a questo fornitore