Video

1 / 3

PVC I raccordi per tubature ad iniezione stampati a iniezione

$20000.00

≥2000 Piece/Pieces

| Model No. : | CT-2024312-05 |

|---|---|

| Brand Name : | Ceeto |

| place of origin : | China |

Ningbo, Zhejiang, China

- Produttore

- Fornitore Oro

- Certificazione della piattaforma

- Expo online

Descrizione del prodotto

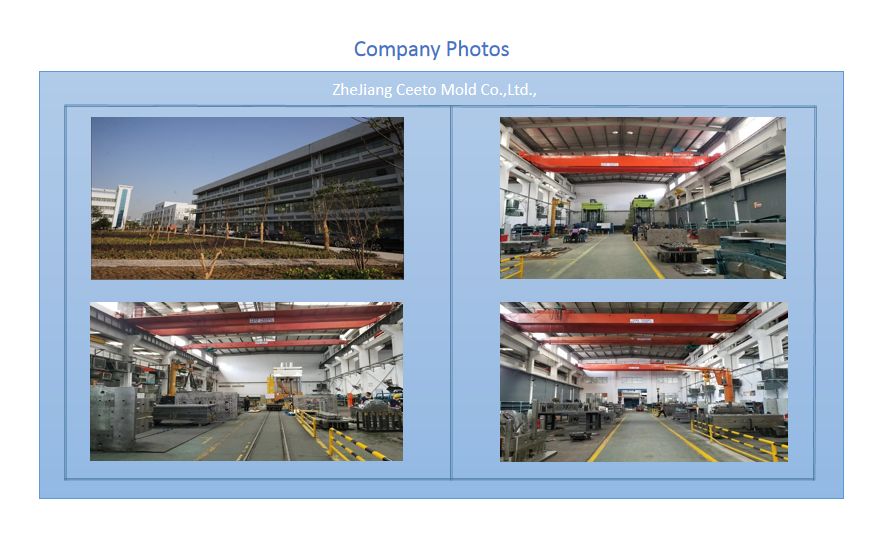

Over twelve thousand square meters machining building area, Zhejiang Ceeto Mold Company has been dedicated to design and manufacture high quality plastic injection mods in many fields such as Automotive industry especially new energy industry, home appliance industry, daily consumer industry, medical consumer industry and so SU.

Large water mouth mold (also known as single parting surface mold),

Extrusion molding is a common production process, usually used to produce plastic products, metal products and rubber products. The process includes the following steps:

1. Raw material preparation: Prepare the required raw materials according to a certain formula, usually the granular or powdered raw materials into the hopper of the extruder.

2. Heating and melting: the raw material is heated and melted in the extruder to make it into a flowing state for subsequent extrusion molding.

3. Extrusion molding: The melted raw material is extruded through the extrusion mold, usually through the screw of the extrusion machine to push the raw material into the mold, and then apply a certain pressure to form the desired shape in the mold.

4. Cooling and curing: extrusion products need to go through the process of cooling and curing to maintain the desired shape and performance.

5. Cutting and post-treatment: Extrusion products usually need to be cut, trimmed and surface treatment and other subsequent processes to meet customer needs.

Extrusion molding process has the advantages of high production efficiency, low cost and short production cycle, so it is widely used in various industrial fields.

…… FAQ ……

Visualizza di più

Video

Ningbo, Zhejiang, China

- Produttore

- Fornitore Oro

- Certificazione della piattaforma

- Expo online

Invia la tua richiesta a questo fornitore